NOS430 Die Steel for Hot Forging Toolings, Super Purity Die Steel

Features

NOS430, originates from SUPER technology and is a type of hot work tool steel with high purity, homogeneous annealing structure, excellent thermal conductivity and temper softening resistance.

NOS430 is applied for middle-large sized hot stamping, brass hot forging, die casting core insert and brass extrusion, which are working under high temperature.

NOS430 is strictly inspected as per standard NADCA#229-2011, and other properties also can be tested as customers' requirement.

Chemical Composition (%)

C | Si | Mn | P | S | Cr | Mo | V |

0.38 | 0.15 | 0.40 | ≤ | ≤ | Patented | ||

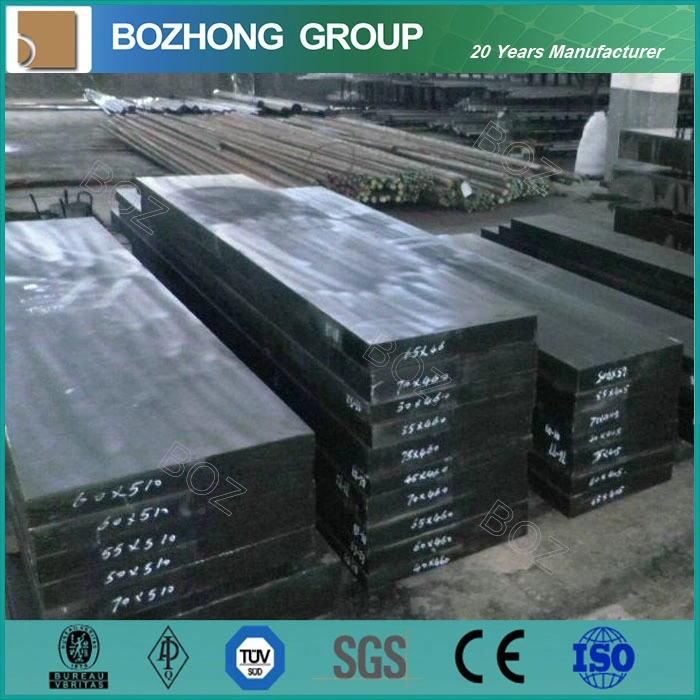

Dimensions

Shape | Thick / Dia. (mm) | Width (mm) |

Round | 100-500 | / |

Block | 100-400 | 200-1000 |

Delivery Condition

EAF+LF+VD+ESR, Forged, Spheroidizing Annealed, EFS, Hardness≤200HB, Black surface or Machined surface,

UT 100% Passed

Take the advanced melting process for smelting and refining to get the super purified and homogeneous steels.

Take the advanced 3D forging technology to thinning the structure; eliminate the internal defect like shrinkage cavity and porosity; break the big-sized carburization and reduce the band segregation. It is helpful to reduce the discrepancy in the different directions of the steel.

Take the advanced Super-fining heat treatment technology to get the small grain size and homogeneous structure.

Take the strict inspection for each piece of steel products according to the most advanced standard. Ensure our customers use the steels with excellent and stable quality.

Physical Property (Q+T to be 45HRC)

Temperature | Density | Elasticity Modulus | Thermal Expansivity | Thermal Conductivity |

20 | 7800 | 210000 | -- | -- |

400 | 7700 | 180000 | 12.6 | 33 |

600 | 7600 | 145000 | 13.2 | 33 |

Mechanical Property (Room temperature, S-T direction)

Hardness | Tensile Strength (Rm) | Yield Strength (RP0.2) |

48 | 1620 | 1400 |

45 | 1470 | 1470 |

40 | 1250 | 1250 |

Heat Treatment

Soft Annealing

Heating steels upto 820ºC in protective atmosphere; after soaking, then have cooling in the furnace at the rate of 10ºC/hr; after temperature comes down to 650ºC, finally have air cooling.

Stress relieving

Stress Relieving should be done on the die after rough machining, heating upto 650ºC, heat preservation for 2 hours; Slow cooling down to 500ºC, further air cooling.

Hardening

Refer to Hardening Diagram,

Preheating in two steps as per A: 600ºC and B: 850ºC.

Austenization as per C: 1020-1050ºC

Direct cooling as per D, or Sectionalized cooling as per E:500-550ºC

Hardening Diagram Tempering Diagram

Tempering

Refer to Tempering Diagram. Choose the proper tempering temperature for required hardness.

For die casting mould, temper at least 3 times.

For hot forging die and extrusion die, temper at least 2 times.

After tempering, it must need cooling down to room temperature.

Holding time for tempering is 2 hours min..

Tips: To avoid the temper brittleness, don't temper in 500-550ºC.

Hardness: HRC Residual Austenite %

Tempering Temperature (2h+2h) ºC

Tips

1. Holding time means the duration of die steel from total heating to Austenitization.

2. During hardening process, steel must be heated to avoid oxidation or decarburization.

3. Steels need to be tempered immediately when temperature gets down to be 50-70ºC.

4. To get excellent property for the die, the quenching speed should be as fast as possible,

but should avoid the case of being out of shape or cracks.

If you need more details, please refer to "Heat Treatment Manual" or consult us.

Quenching Holding Time and Thickness

Thickness | Time | Thickness | Time |

5 | 60 | 50 | 300 |

10 | 90 | 60 | 390 |

20 | 160 | 70 | 420 |

30 | 240 | 80 | 440 |

40 | 280 | 90 | 495 |

Product Application

Industry | Features | Steel Grade Recommendation |

Die Casting | Die Casting is a kind of metal casting technique. It is characterized by using the mould cavity to have high pressure on molten metal. It has the good performance in anti heat cracking, anti corrosion, anti-crack, red hardness. | NOS411, |

Hot Extrusion | Before extrusion, heat the metal over temperature of recrystallization. It has the good strength at high temperature, high ductility and good toughness, high thermal fatigue resistance and thermal wear resistance, as well as the anisotropic properties of consistency. | NOS411, |

Hot Forging | Hot forging is a kind of processing under the condition of over the temperature of recrystalization. It has the good thermal wear resistance, heat intensity, high ductility and good toughness, high thermal conductivity. | NOS411, |

Hot Stamping | Hot Stamping is the rapid molding in the mould blank and hardening heat. It has the good thermal conductivity, hot bending strength, high toughness and ductility. | NOS411, |

Injection Molding | Injection molding is a kind of forming process of injection and molding at the same time. It has the high polishability, good corrosion resistance, wear resistance, anti-cracking and thermal conductivity. | NOS411, |

Compression Molding | Compressing Molding is a process of solidifying the thermosetting plastics through heating and pressing. It is usually used for plastic molding with reinforced glass fiber. It has the good wear resistance, strength, hardness and corrosion resistance. | NOS411, |

Blow Molding | Blow Molding is a process blowing the raw materials in the closed mould to be the hollow products by gas pressure. It has the medium strength and wear resistance, good thermal conductivity and corrosion resistance. | NOS411, |

Extrusion Molding | Extrusion Molding is a kind of process making the heat plasticized materials to be a specific profile though extrusion. It has the medium strength, but high demand on corrosion resistance and wear resistance. Nitridation is generally used for the mould of fiber reinforced products. | NOS411, |

Performance Comparison

What we can offer

What we can offer?

We offer a wide range of steel products in a wide variety of dimensions and executions, acc.to the common international specifications or customerized.

Machining and heat treatment are available.

Also, we advise you in choosing the right materials.

Shape Available

Solid round bar

Flat bar

Square bar

Hexagon bar

Block

Plate

Sheet

Wire rod

Strip

| AISI | DIN | JIS | Stock | Application |

Hot Work Tool Steel | H11 | 1.2343 | SKD6 | √ | Die Casting Dies,Extrusion Dies, Hammer Dies, |

H13 | 1.2344 | SKD61 | √ | ||

H10 | 1.2365 | SKD7 |

| ||

-- | 1.2367 | -- |

| ||

L6 | 1.2714 / 1.2713 | SKT4 | √ | ||

H12 | 1.2606 | SKD62 |

| ||

H21 | 1.2581 | SKD5 | √ | ||

Cold Work Tool Steel | D3 | 1.2080 | SKD1 | √ | Cutting Tools, Punching Tools, Shear Bladers, Reamers, Thread Rolling Dies, Calipers, Sockets etc. |

-- | 1.2601 | ~SKD11 | √ | ||

D2 | 1.2379 | ~SKD11 | √ | ||

-- | 1.2379 MOD | DC53 (Daido) | √ | ||

D6 | 1.2436 | -- |

| ||

O1 | 1.2510 | SKS3 | √ | ||

O2 | 1.2842 | -- |

| ||

A2 | 1.2363 | SKD12 |

| ||

S1 | 1.2550 | -- |

| ||

S7 | 1.2357 | -- |

| ||

-- | 1.2767 | SKT6 |

| ||

L2 | 1.2210 | -- |

| ||

Plastic | P20 | 1.2311 | -- | √ | Mold Base, Core & Cavity, Bumper Mold etc. |

P20+Ni | 1.2738 | -- | √ | ||

P20+S | 1.2312 | -- | √ | ||

-- | 1.2316 | -- |

| ||

420 | 1.2083 | SUS420J2 | √ | ||

-- | -- | NAK80 (Daido) | √ | ||

Alloy Steel | 4120 | 25CrMo4 / 1.7218 | SCM420 |

| Shafts, Gears, Drillers, Chains, Bolts, Nuts, Pins, Suds, Keys, Bites, Crankshafts, Connecting Rods, Came, Couplings etc. |

4135 | 34CrMo4 / 1.7220 | SCM435 |

| ||

4130 | 34CrMo4 / 1.7220 | SCM430 | √ | ||

4140 | 42CrMo4 / 42CrMoS4 / 1.7225 | SCM440 | √ | ||

4142 | 41CrMo4 / 1.7223 | SCM440 |

| ||

4145H | -- | -- |

| ||

4330V | -- | -- |

| ||

4340 | 34CrNiMo6 / 1.6582 | SNCM439 |

| ||

5115 | 16MnCr5 / 16MnCrS5 / 1.7131 |

|

| ||

5120 | 20MnCr5 / 20MnCrS5 / 1.7147 | SMnC420H |

| ||

5140 | 41Cr4 / 41CrS4 / 1.7035 | SCr440 | √ | ||

8620 | 21NiCrMo2 / 1.6523 | SNCM220 |

| ||

8640 | 40NiCrMo2-2 / 1.6546 | SNCM240 |

| ||

-- | 18CrNiMo7-6 / 17CrNiMo6 / 1.6587 | -- |

| ||

9840 | 36CrNiMo4 / 1.6511 | -- |

| ||

E71400 | 41CrAlMo7-10 / 1.8509 | SACM1 |

| ||

-- | 34CrAlNi7 / 1.8550 | -- |

| ||

Bearing Steel | E52100 | 100Cr6 / 1.3505 | SUJ2 | √ | Bearing, Shafts |

-- | 100CrMn6 / 1.3520 | -- |

| ||

-- | 100CrMo7-3 / 1.3536 | -- |

| ||

Spring Steel | 5155 | 55Cr3 / 1.7176 | SUP9 |

| Springs |

6150 | 51CrV4 / 1.8159 | SUP10 |

| ||

9261 | 60CrSi7 / 1.7108 | -- |

| ||

Carbon Steel | 1010 | CK10 / C10E / 1.1121 | S10C |

| Shafts, Chains, Bolts, Nuts, Pins, Suds, Keys, Bites, Came, Couplings etc. |

1020 | C22 / 1.0402 | S20C | √ | ||

1040 | CK40 / C40E / 1.1186 | S40C | √ | ||

1045 | CK45 / C45E / 1.1191 | S45C | √ | ||

1050 | CK50 / C50E / 1.1206 | S50C | √ | ||

1055 | CK55 / C55E / 1.1203 | S55C |

| ||

1064 | CK60 / C60E / 1.1221 | S58C |

| ||

High Speed Tool Steel | M2 | 1.3343 | SKH51 | √ | Reamer, |

M7 | 1.3348 | -- |

| ||

M42 | 1.3247 | SKH59 | √ | ||

M35 | 1.3243 | SKH55 | √ | ||

T1 | 1.3355 | SKH2 |

| ||

T15 | 1.3202 | -- |

| ||

T42 | 1.3207 | SKH57 |

|

Note:

1). √ means we have stoc

2). Delivery Condition:

Smelting: EAF+LF+VD (+ESR)

Making: Hot rolled, Cold rolled, Forged, Cold Drawn

Heat Treatment: Untreated, Annealing, N+T, Q+T

Surface: Black, Peeled, Turned, Milled, Grinded, Polished

Company Information

Bozhong Group Mainly supply in forms of coil, sheet, plate, rod, bar, tube, pipe, beam, angle, flange, wire, strip, channel, etc., with various varieties, wide range of dimensions, high purity, stable chemical composition, high dimensional accuracy and excellent surface quality. The products are mainly used in the fields of industries such as automobile engineering, railway transportation, aviation, aerospace, machinery, petrochemical, energy, environmental protection, offshore, chemical, oil & gas, ilitary, power plant, nuclear power, pressure vessel, boiler equipment, mold manufacture, etc.

steel coil

l steel plate

l steel sheet

l steel bar/rod

steel round bar

steel flat bar

steel square bar

l steel pipe/tube ( welded or seamless )

steel round pipes

steel square pipes

steel welded tubes

steel seamless tubes

l steel strip

l steel beam

l steel angle

l steel channel

l steel flange

l Steel wire

Bozhong Group can supply a variety of structural steel, high-strength steel, wear-resistant steel plate, boiler and pressure vessel steel, marine engineering and stainless steel plate in the thick steel and various European standard bars and pipes and profiles.Our global sales and service network throughout all around the world to ensure that the goods reach the customer in the shortest time.

We can follow your drawings and requirements, to provide you with oxygen cutting, plasma cutting and laser cutting and other processing services. You can also perform ultrasonic testing in accordance with EN10160 standard, EN10164 standard test Z15, Z25, Z35, weld bending detection, PWHT detection,etc.

We have ISO9001: 2000 quality management system certification, and obtain the quality certification from all the well-known certification company, including TuV / LRS / GL / CE and so on.

Special steel includes as below:

Boiler and pressure vessel steel

Pipeline steel

Bridge steel

Nuclear power steel

Structural steel

Die steel

High strength steel

Abrasion resistant steel

Weathering, corrosion resistant and fire resistant steel

High rise building steel

Shipbuilding and offshore engineering steel

Q: Are you a manufacturer or merely a trader?

A: We are group of companies and owned manufacturer bases and trading company. We specialized in special steel which include alloy structural steel and carbon steel and stainless steel, etc. All material are with high quality and competitive price.

Q: How do you guarantee the quality of your product?

A: Firstly, we can provide the certificates from the third party, such as TUV, CE, if you need. Secondly, we have a complete set of inspection system and every process is checked by QC. Quality is the lifeline of enterprise survival.

Q: Delivery time?

A: We have ready stock for most of material grades in our warehouse. If the material don't have stock, the delivery lead time is about 5-30 days after receiving your prepayment or firm order.

Q: What is the payment term?

A: T/T or L/C.

Q: Can you provide a sample for our testing before confirm the order?

A: Yes. We can provide sample to you for approval before you place an order to us. Free sample is available if we have stock.

Q: Can we visit your company and factory?

A: Yes, warmly welcome! We can book the hotel for you before you come to China and arrange our driver to our airport to pick you up when you come.

Customer Visiting:

Warmly welcome! Pick up your phone and Call us!

Send us the inquiry here!

We will reply you at the first time.

Packing & Shipping

Hot keywords:high quality