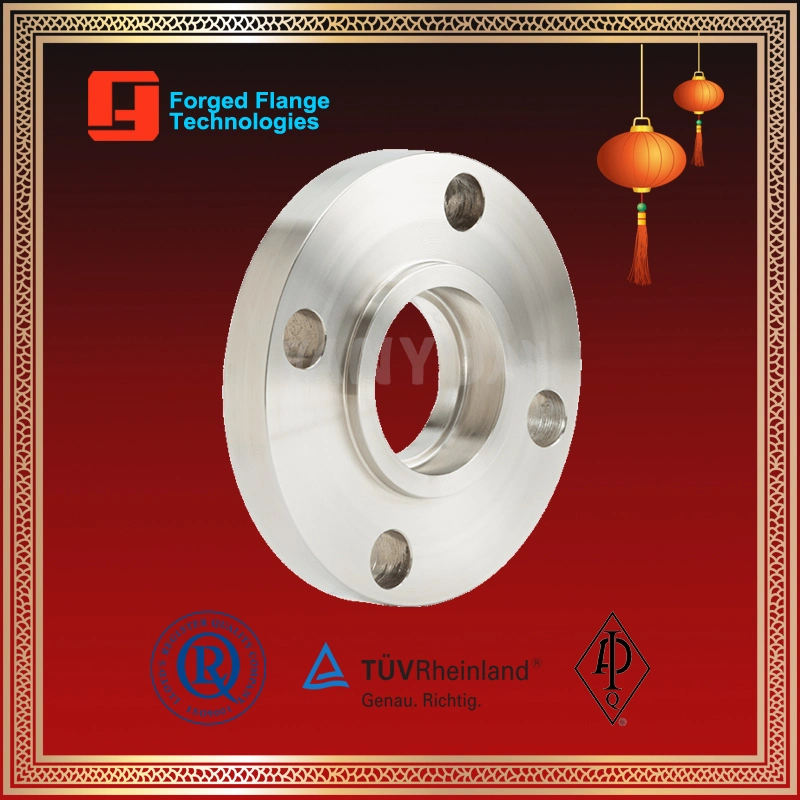

DETAILS OF SOCKET WELD FLANGE 1. Socket Weld flange 2. Filled weld 3. Pipe X = Expansion gap |

Socket Weld or Socket Welding Flanges

A socket weld flange consists of a socket in which a pipe is secured by a fillet weld at the hub on the outside. As per ASME B31.3 an approximate gap of 1⁄16 inch as shown in Fig. 328.5.2B and Fig. 328.5.2C is required to be present before any welding, including tack welding. If this gap is not maintained, the heat input during welding can cause the pipe to touch the bottom of socket due to differential expansion between the flange and pipe, and cause the weld to crack. The gap between the socket and the pipe is a source of crevice corrosion in the socket weld piping system.

Since socket weld flanges are attached to the pipe by fillet weld they are not considered as high-integrity joints. The joint being a fillet weld cannot be subject to radiography. Non destructive examination of socket weld flanges is carried out by magnetic particle examination or liquid penetrant examination. Though socket weld flanges are available up to 2½ inches in class 1500 rating, they are in most cases used for sizes up to 1½ inches and below and for non-critical applications. Socket weld flanges are not specified in class 2500 rating as per ASME B16.5. A socket welding flange is subject to the requirements for socket welds in para. 311.2.4 of ASME B31.3. This limits the use of socket welded flanges in any service where crevice corrosion or severe erosion may occur

Maximum weight 6tons

25,000tons production annual year

API 605,API 16D,API 17D

BS4504,BS3293

DIN

AS

EN1092-1

GOST

EEMUA145

EN10204-3.2 byTUV,BV,Lloyds,GL,DNV,SGS,ABS,RINA,Moody or other tird parties