by MIKE PREVOST, Vice President of Specialty Services, Ohmstede Industrial Services

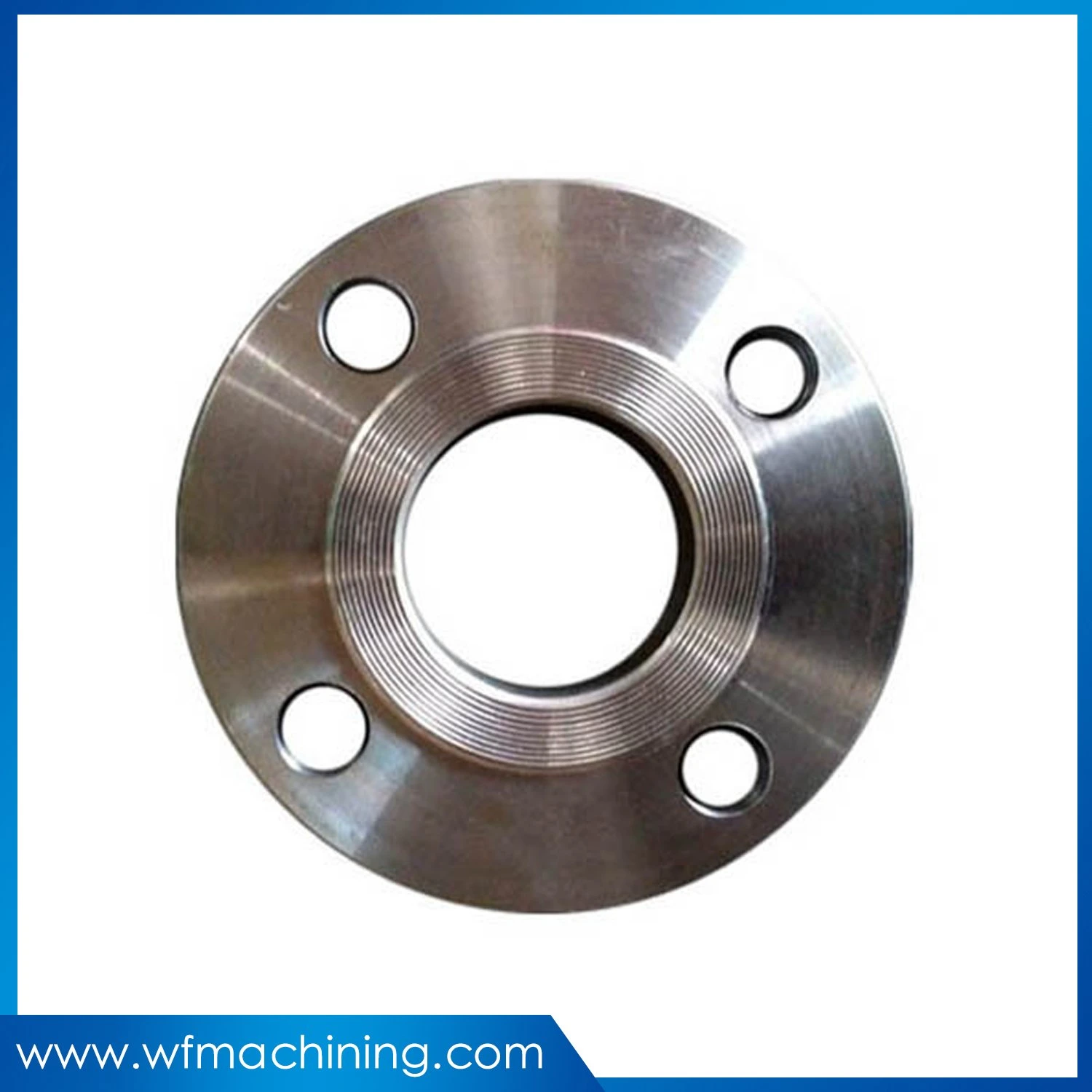

Bolted flange joint connections should not leak on heat exchangers, but they often do because of design and/or assembly issues. However, by giving proper attention to the factors that most significantly influence bolted assemblies, it is possible to achieve leak-free connections on heat exchangers.

It is possible to achieve leak-free connections on heat exchangers.

Before disassembly, there are several key factors to consider for avoiding flange joint leaks. First, the temperature, pressure and effect of the product properties on the bolted flange joints must be understood, followed by selecting the suitable materials and gaskets.

Identify any areas of concern. Consider whether the existing bolts, nuts and gaskets were the best selections based on the heat exchanger's temperature, pressure and service during this evaluation stage.

After disassembly, note the position of the existing gasket and any signs of erosion or pitting on the flange face surface. Also, verify the flatness of the mating surfaces. Many issues can be prevented by following the recommendations set forth in ASME PCC-1. Once the gasket surface is verified, a crew's next step is to verify they have the correct gasket, bolts, nuts and (if applicable) washers, along with the correct lubricant. Much like an airline pilot has a pre-flight checklist, it is a good practice to have a flange joint inspection and verification checklist to help eliminate potential issues during the disassembly and reassembly of exchangers.

Bring engineering, flange assemblers together

Effective bolted flange joint assembly involves more than just a crew putting its hands on the flange. It all begins with engineering and determining the correct materials for the process application. The engineering design parameters must then be communicated effectively to the assemblers to achieve the greatest influence on the quality of the outcome.

There is no substitute for knowledgeable and qualified bolt assemblers. The way to ensure proper assembly is to ensure that the assemblers are experienced and understand what good, bad and ugly look like in the field. A key factor for achieving leak-free exchangers is to ensure both engineering and qualified and experienced assemblers are involved in the process.

By following the ASME PCC-1 guidelines and using trained bolting personnel, owners can dramatically improve the likelihood of achieving leak-free exchangers. A key reason to use certified bolting personnel is because they inspect and address:

Flange joint connections are dynamic, but with proper understanding, management and application, there are many opportunities to achieve leak-free performance on exchangers. By following the ASME PCC-1 guidelines and using qualified bolting personnel, the odds of achieving leak-free exchangers improve dramatically. From a technical and application perspective, we invite readers to contact one of the industry's premier exchanger maintenance contractors, Ohmstede Industrial Services, for your next project.

For more information, visit www.ohmstede.com or call (281) 867-3260.

by MIKE PREVOST, Vice President of Specialty Services, Ohmstede Industrial Services

Connecting people in business and industry with one another for the betterment of all. Become an Alliance Member today

Copyright © 2022 BIC Alliance, Inc. All rights reserved.